| Explosion Protection |  |

|

| تجهیزات و لوازم ضد انفجار |  |  |

Hazardous zones

Hazardous areas are classified into 'ZONES' which indicate the probability of an explosive gas-air mixture being present and, therefore, the likelihood of an explosion occurring .

Zone 0 In which an explosive gas-air mixture is continuously present, or present for

long periods.

Zone I In which an explosive gas-air mixture is likely to occur in normal operation.

Zone 2 In which an explosive gas-air mixture is not likely to occur in normal

operation and, if it occurs, will exist for only a short time. An area which is

not classified Zone 0, I or 2 is assumed to be a non-hazardous or 'safe' area.

Examples of this zoning applied to ships could be :

ZONE 0 Interior spaces of oil cargo tanks, pipes, pumps, etc.

ZONE I Enclosed or semi-enclosed spaces on the deck of a tanker, the boiler firing

area on a gas carrier using methane boil-off as a fuel and battery rooms.

ZONE 2 Open spaces on the deck of a tanker. The cargo pump rooms of tankers are,

at present, considered as falling somewhere between ZONE 0 and ZONE I .

Electrical ignition of gas

concentrated above the Lower Explosive Limit (LEL), e.g.

(i) Arcing between switch contacts.

(ii) Arcing between a live conductor and earth.

(iii) An internal arcing fault within an electrical enclosure.

(iv) Overheating causing 'hot spots'.

(v) An electrostatic spark discharge between charged bodies or between

a charged body and earth.

(vi) Chemical action.

(vii) Lightning strikes.

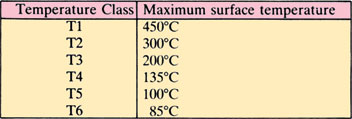

Temperature class

This defines the maximum suTrface temperature of the components in the electrical equipment under normal and fault conditions. This maximum surface temperature must not exceed the gas ignition temperature. The temperature class is stated with reference to a maximum ambient temperature of 40°C.

should any other reference temperature be adopted, regulations require that this temperature be shown on the equipment. It is important to note that the apparatus gas grouping and temperature class are not related.

For instance, hydrogen requires very little spark energy to ignite, but the surface temperature necessary for ignition is very high (560°C). The following table relates the temperature class to the maximum surface temperature under fault conditions .

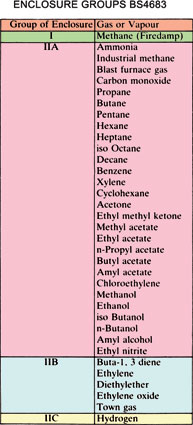

Apparutus gas groups

The flammable gases in which explosion protected electrical

equipment may have to operate are grouped according to the amount

of electrical energy, in the form of an arc. which is needed to ignite the

gas.Gases associated with the mining industry are classed as

GROUP I. all other industrial gases are classed as GROUP II in four

sub-groups according to their ease of ignition.

It should be noted that equipment certified for use in GROUP IIC

may also be used for IIA and IIB.

Equipment certified for IIB may be used for IIA.

Equipment certified for IIA may be used with no other group.

The gas grouping can affect the design and construction of some

types of explosion protected equipment (Exd and Exi),

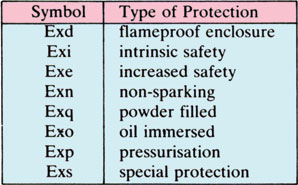

Types of Explosion protection

preventing electrical equipment causing explosions in hazardous areas. Some techniques, such as flameproof enclosures, have long been established but others, such as intrinsic safety and increased safety, are the result of more recent developments in electronics and materials . It has been internationally agreed that explosion protected equipment be identified by the symbol 'Ex' followed by a letter indicating the type of protection employed. The following table lists the types of protection and their symbols :

Some equipment may use more than one of these types of protection in its construction . In this case, the primary type of protection is quoted first. For example, an increased safety motor with a flameproof terminal box would be marked Exe,d.

Ex'd' Flameproof Enclosure

A flameproof enclosure is one wich will withstand , without damage , an

explosion of the flammable gas within itself , and will prevent transmission of

the flame wich could iginte the gas in the surrounding atmosphere.

Ex'i' intrinsic safety

These are circuits in which no spark nor any thermal effect produced under

prescribed test conditions (which include normal operation and specified fault

conditions) is capable of causing ignition of a given explosive atmosphere .

Generally, this means limiting the circuit conditions to less than 30V and 50mA .

Naturally, this restricts the use of Exi protection to low power instrumentation ,

alarm and communication circuits. The design of the circuit will depend on the

type of gas present (gas grouping) .

In the UK two grades of Intrinsic Safety are recognised based on the safety

factor of the equipment involved. Exia - the highest category based on a safety

factor of 1.5 with two faults on the circuit .

Exib - based on a safety factor of 1.5 with only one fault on the circuit .

In addition to apparatus in the hazardous area being rated as intrinsically safe ,

an electrical safety barrier may also be fitted to the circuit. The purpose of such

a barrier is to limit voltages and currents in the hazardous area when faults

occur on the circuit. A separate barrier is required for each Exi circuit and they

must be fitted outside the hazardous area .

A safety (or zener) barrier comprises :

(a) A fuse to limit the maximum current through the shunt diodes.

(b) A set of resistors to limit the maximum current into the hazardous area.

(c) A set of shunt connected zener diodes to limit the maximum voltage

appearing on the circuit within the hazardous area .

Ex'e' Increased Safety

This is a specification which was originally devised in Germany . Increased safety

equipment is based primarily on the elimination of 'open sparking' as at relay

and switch contacts or on the commutators or slip rings of motors and

generators, and on the close control of surface temperatures. Also the

construction of the equipment is to a very high standard to prevent faults

developing. Extra insulation is used, creepage distances between bare terminals

are made longer and special enclosures to protect against damage due to entry

of moisture and mechanical damage are also specified.

Ex'n' Non-Sparking

A new British classification derived from the German Exe but less

exacting and is therefore more restricted in its application.

Ex'q' Sand Filled

Same idea as the oil immersed except that quartz 'sand' is used

rather than oil. An HRC fuse-link is sand filled.

Ex'o' Oil Immersed

This involves placing equipment in oil-filled tanks to prevent gas

from reaching any arcs that may be produced.

Ex'p' Pressurised Enclosure

Air or inert gas is supplied to the equipment slightly above

atmospheric pressure to prevent entry of the flammable gas .

This method is sometimes used for pumproom lighting.

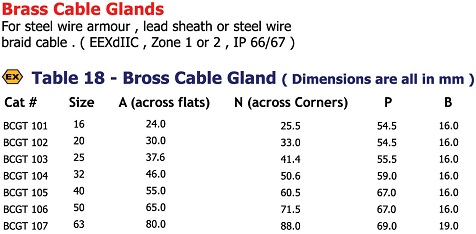

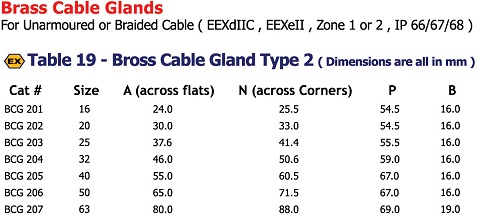

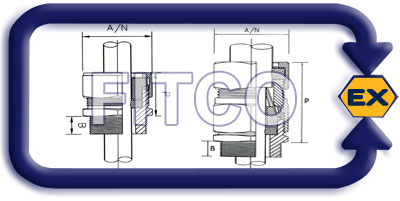

گلند کابل ، ضد انفجار ، واتر پروف

گلند کابل ، ضد انفجار ، واتر پروف

|  |

|

| Explosion Protection |  |

|